In Industry 4.0, a dynamic fusion of technologies and manufacturing expertise is reshaping industries worldwide. This blog takes inspiration from research institutions. Provides an in-depth exploration of the transformative power of Industry 4.0 and practical examples of how companies can embrace this revolution. My previous post discussed how Digital Transformation is Fueling Business Agility.

Exploring the Fundamental Principles of Industry 4.0

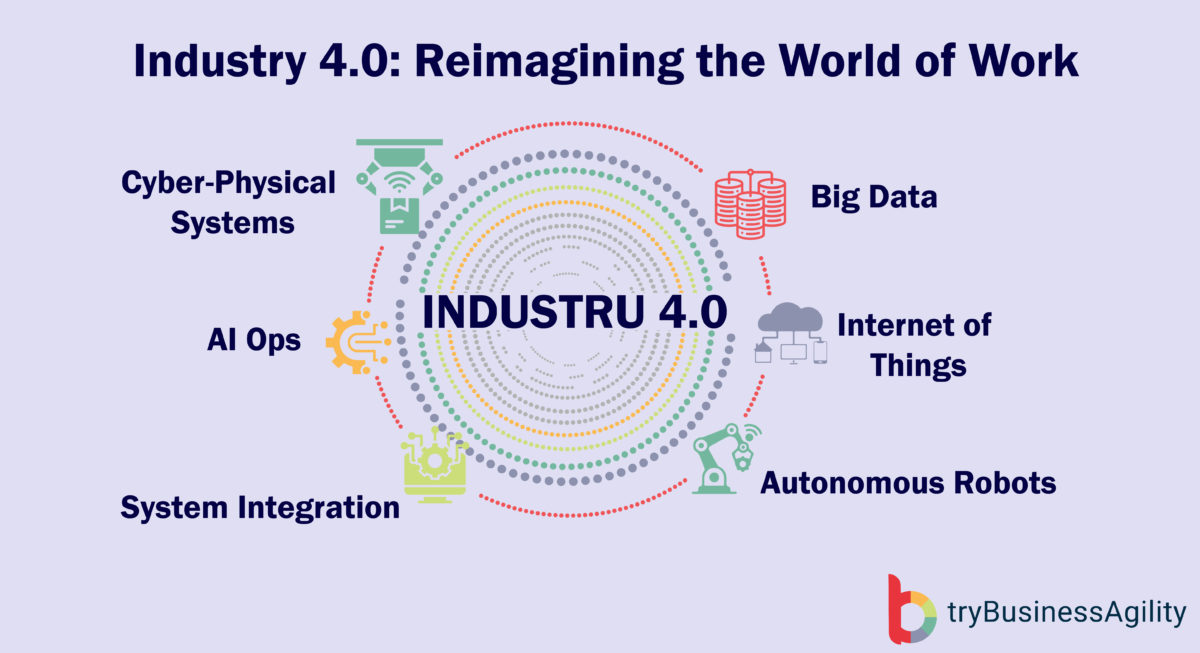

As per our understanding, Industry 4.0 represents the convergence of cutting-edge technologies such as intelligence, IoT (Internet of Things), big data, and robotics. This combination of digital realms holds the potential for increased efficiency, productivity, and innovation, paving the way for a future where industries operate with unparalleled precision.

MIT Vision for Cyber-Physical Systems;

One of the critical tenets of Industry 4.0 is Cyber-Security. The Massachusetts Institute of Technology (MIT) has been at the forefront of unlocking the possibilities presented by Industry 4.0 through its focus on cyber systems. MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) has conducted groundbreaking research that showcases how these systems seamlessly integrate processes with intelligence. Implementing systems has shown results in potentially reducing operational costs by 10% and boosting production output by up to 20% within the next decade (“Advancing the Future; Industry 4.0 Research, at MIT ” CSAIL, MIT).

Robotics

Stanford University emphasizes robotics, which is a fundamental aspect of Industry 4.0. The researchers at Stanford Artificial Intelligence Lab have played a role in demonstrating how robots with sensing capabilities can work alongside human workers in factories. This collaborative approach does not boost productivity. It also creates a safer and more dynamic work environment (“Human Robot Collaboration for Enhanced Manufacturing ” Stanford AI Lab).

Big Data and Analytics

Through efforts between Harvard Business School and the School of Engineering and Applied Sciences, they have shown how harnessing data’s power can revolutionize manufacturing decision-making. When working with companies, we have observed that many are utilizing big data and analytics as enablers to support their product operations.

Companies that utilize data analytics experience a 15% reduction in defects and a 20% improvement in supply chain efficiency, highlighting the impact of data-driven insights (“Big Data Revolutionizing Manufacturing,” Harvard Business Review).

To embrace Industry 4.0, companies can transform their factories into intelligent and connected hubs. A prime example is Bosch, a global technology company that has initiated the “Connected Industry” project.

By combining Internet of Things (IoT) devices with real-time analytics, Bosch has optimized production processes, reduced downtime, and improved efficiency.

Another remarkable progress in embracing robotics is ABBs YuMi. YuMi is designed to work alongside operators in electronics assembly and perform tasks. This collaboration does not speed up production. It also enables more intricate and precise manufacturing. This is where the Missing Middle Skills are necessary to embrace this change and provide employees with a safe working environment.

Siemens promotes data-driven decision-making through its Digital Twin concept. By creating a replica of assets and processes, Siemens allows companies to simulate, analyze, and optimize operations in real time. This technology has proven invaluable in predicting and preventing equipment failures and enhancing reliability.

How about Born Digital Companies?

Often, we get a question that this does not apply to Born digital companies, which are deeply rooted in technology and are at the forefront of embracing the power of Industry 4.0. But, we firmly believe they have a bigger fish to fry than the conventional companies. I will share some examples that I have come across here.

Spotify- Pioneering Industry 4.0 in the Entertainment World;

As a company born in the music industry, Spotify seamlessly incorporates Industry 4.0 principles into its operations, revolutionizing the music streaming landscape. Using data analytics and artificial intelligence, Spotify creates playlists and recommendations tailored to each user’s preferences. The company’s algorithms enhance consumer experiences and optimize content delivery efficiency, showcasing how Industry 4.0 shapes the entertainment sector.

Uber- A Leader in Mobility During an Era of Connectivity

Uber, a trailblazer in the mobility industry, embodies a born entity that thrives on innovations by Industry 4.0. The platform integrates technologies such as real-time tracking through IoT pricing using machine learning algorithms and collaborative technologies for their autonomous vehicle projects that evolve. Uber’s dedication to transforming transportation through advancements reflects how born-digital companies can reshape industries by embracing Industry 4.0 principles.

Airbnb Reimagining the Hospitality Industry

A disruptor in the hospitality industry is a born company that utilizes the principles of Industry 4.0 to redefine the concept of accommodation. Their platform incorporates technologies for booking and utilizes data analytics to understand user preferences and deliver personalized experiences. By embracing the connectivity and intelligence of Industry 4.0, Airbnb has disrupted hospitality and established new standards for customer-centric services in the digital era.

Industry 4.0 is not a vision; it is a tangible reality shaping the future of industries. As companies navigate this paradigm shift, incorporating technologies such as factories, collaborative robotics, and data-driven decision-making becomes crucial.

Conclusion

At tryBusinessAgility, our mission is to discover, preserve, and distribute knowledge and capabilities to enable the next generation of organizations to be capable and resilient. By upskilling the next generation of the workforce through our offerings, we believe that we can help organizations build capable and resilient workplaces that swim through the Industry 4.0 tediums.

13 replies on “Industry 4.0: Reimagining the World of Work”

Hi,Check out [www.dramago.live] for all your favorite Korean series. They have a huge variety of the latest and popular dramas you can watch anytime on any device.Thanks!

Hi,Check out [www.dramago.live] for all your favorite Korean series. They have a huge variety of the latest and popular dramas you can watch anytime on any device.Thanks!

This post is a gem! Your passion for the topic is evident. Thank you for the valuable insights. Can’t wait to read more from your blog. Keep up the excellent work!

Hi,Check outhttps://sites.google.com/d/1LZ5xqiGyyGneC2ELnm2vfh72L607ibpx/p/1ikhzqis3KR7V6QSgT_hDBZizKzcxLagc/edit for all your favorite series.

Hi,Check out [www.dramago.live] for all your favorite Korean series. They have a huge variety of the latest and popular dramas you can watch anytime on any device.Thanks!

Check out Followerswift for amazing social media growth!

I like this website it’s a master piece! Glad

I found this ohttps://69v.topn google.Raise blog range

Howdy! Do you know if they make any plugins to help with Search Engine Optimization?

I’m trying to get my site to rank for some targeted keywords but

I’m not seeing very good gains. If you know of any please share.

Kudos! You can read similar article here: Eco wool

많은 친구들에게 추천하고 싶어요! 방문하다 먹튀레이더

Hi there! Do you know if they make any plugins to assist with SEO?

I’m trying to get my website to rank for some targeted keywords but I’m

not seeing very good success. If you know of any please share.

Appreciate it! You can read similar article here: COD

I’m extremely impressed with your writing talents as neatly as with the structure on your blog. Is that this a paid subject or did you modify it yourself? Anyway keep up the excellent quality writing, it is uncommon to look a great weblog like this one nowadays. I like cms.trybusinessagility.com ! Mine is: Stan Store alternatives

I’m extremely impressed together with your writing abilities and also with the format for your weblog. Is this a paid subject matter or did you modify it your self? Anyway stay up the nice high quality writing, it is uncommon to look a great blog like this one these days. I like cms.trybusinessagility.com ! I made: Instagram Auto follow

I’m really inspired together with your writing talents and also with the layout for your blog. Is this a paid subject matter or did you modify it yourself? Either way stay up the nice high quality writing, it’s rare to see a nice weblog like this one these days!